Description

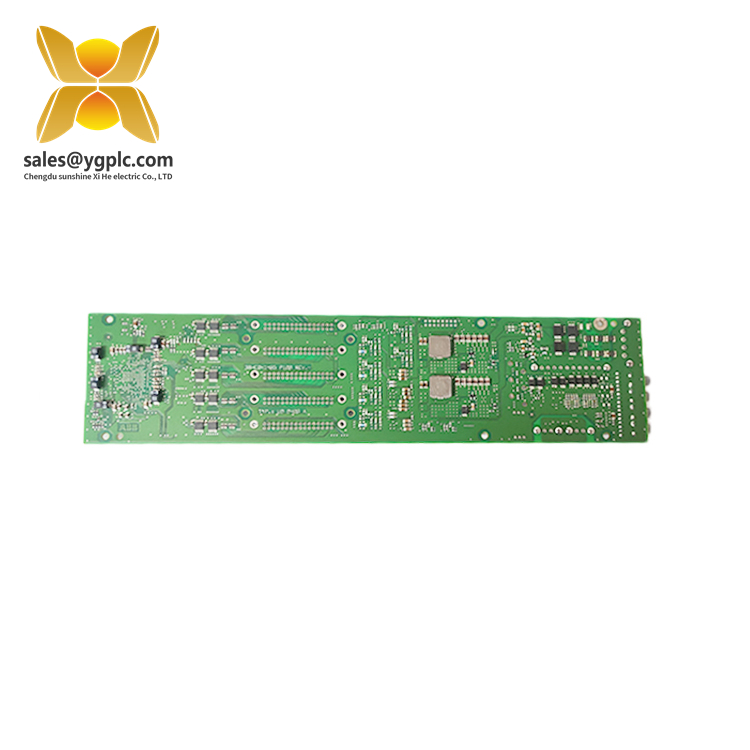

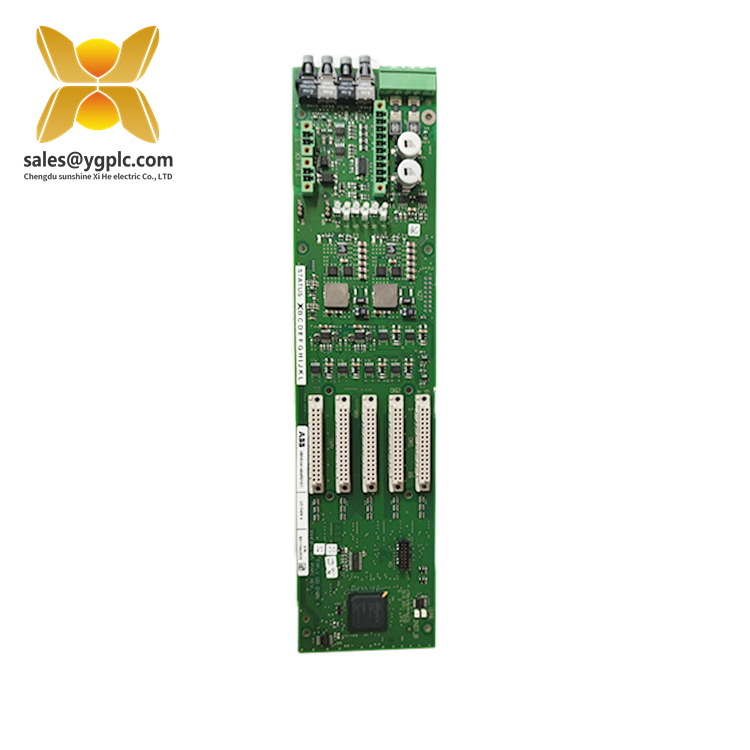

ABB UDD406A Programmable Logic Controller (PLC)

Product Overview

The ABB UDD406A is a high-performance programmable logic controller (PLC) designed to deliver advanced automation and control in industrial environments. As part of ABB’s comprehensive portfolio of industrial automation solutions, this compact yet powerful module combines modular flexibility with robust functionality, making it suitable for diverse applications across manufacturing, energy, transportation, and process industries. The UDD406A supports real-time data processing, precise logic control, and seamless integration with distributed control systems (DCS), enabling operators to optimize efficiency, reduce downtime, and enhance safety. Its user-friendly interface and compatibility with multiple programming languages, including ladder diagram (LD) and function block diagram (FBD), simplify configuration and maintenance, while its rugged construction ensures reliable operation in harsh conditions.

The ABB UDD406A is a high-performance programmable logic controller (PLC) designed to deliver advanced automation and control in industrial environments. As part of ABB’s comprehensive portfolio of industrial automation solutions, this compact yet powerful module combines modular flexibility with robust functionality, making it suitable for diverse applications across manufacturing, energy, transportation, and process industries. The UDD406A supports real-time data processing, precise logic control, and seamless integration with distributed control systems (DCS), enabling operators to optimize efficiency, reduce downtime, and enhance safety. Its user-friendly interface and compatibility with multiple programming languages, including ladder diagram (LD) and function block diagram (FBD), simplify configuration and maintenance, while its rugged construction ensures reliable operation in harsh conditions.

UDD406A

Technical Specifications

| Parameter Name | Parameter Value |

|---|---|

| Product Model | ABB UDD406A (3BHE041465P201) |

| Manufacturer | ABB |

| Product Type | Programmable Logic Controller (PLC) |

| Input Voltage | 24 V DC ±10% |

| Communication Protocols | Modbus RTU, PROFIBUS-DP |

| I/O Channels | 16 digital inputs / 16 digital outputs |

| Memory Capacity | 256 KB user program memory |

| Operating Temperature | -20°C to +60°C |

| Dimensions | 110 mm × 115 mm × 45 mm |

| Weight | 0.98 kg |

| Redundancy Support | Optional dual-channel configuration |

| Programming Languages | Ladder Diagram (LD), Function Block Diagram (FBD) |

Key Features and Advantages

The UDD406A stands out for its versatility and reliability. Its modular design allows easy expansion with additional I/O modules, adapters, and communication interfaces, ensuring scalability for evolving industrial needs. The PLC’s advanced processing unit supports high-speed data acquisition and real-time decision-making, critical for dynamic processes such as assembly line synchronization or energy management. Built-in diagnostics and error alerts enable proactive maintenance, minimizing system disruptions. With EMI shielding and surge protection, the UDD406A maintains stable performance in electrically noisy environments. Compatibility with ABB’s S800 I/O series and third-party devices enhances its integration capabilities, while remote configuration via ABB’s Control Builder software streamlines commissioning.

The UDD406A stands out for its versatility and reliability. Its modular design allows easy expansion with additional I/O modules, adapters, and communication interfaces, ensuring scalability for evolving industrial needs. The PLC’s advanced processing unit supports high-speed data acquisition and real-time decision-making, critical for dynamic processes such as assembly line synchronization or energy management. Built-in diagnostics and error alerts enable proactive maintenance, minimizing system disruptions. With EMI shielding and surge protection, the UDD406A maintains stable performance in electrically noisy environments. Compatibility with ABB’s S800 I/O series and third-party devices enhances its integration capabilities, while remote configuration via ABB’s Control Builder software streamlines commissioning.

UDD406A

Application Areas

The UDD406A excels in a wide range of industrial settings. In manufacturing, it drives automated machinery, ensuring precision control of robotics and conveyor systems. Power generation plants utilize its redundancy features for turbine monitoring and grid stabilization. In water treatment, it manages pump operations and chemical dosing systems. Its compact size and DIN-rail mounting make it ideal for space-constrained applications, such as building automation or transportation infrastructure. By integrating with ABB’s broader automation ecosystem, including the 800xA DCS, the UDD406A supports smart manufacturing initiatives, enabling predictive analytics and energy optimization.

The UDD406A excels in a wide range of industrial settings. In manufacturing, it drives automated machinery, ensuring precision control of robotics and conveyor systems. Power generation plants utilize its redundancy features for turbine monitoring and grid stabilization. In water treatment, it manages pump operations and chemical dosing systems. Its compact size and DIN-rail mounting make it ideal for space-constrained applications, such as building automation or transportation infrastructure. By integrating with ABB’s broader automation ecosystem, including the 800xA DCS, the UDD406A supports smart manufacturing initiatives, enabling predictive analytics and energy optimization.

Related Products

- ABB UCD224A102: A high-capacity I/O module for distributed control systems.

- ABB PFEA112-20: Tension control module for precision material handling.

- ABB S800 I/O Modules: Expandable I/O solutions for decentralized automation.

- ABB 800xA DCS: Comprehensive distributed control system for large-scale operations.

- ABB UAD155A0111: Power distribution module for redundant power supply setups.

UDD406A

Installation and Maintenance

Installation Preparation:

Mount the UDD406A securely on a DIN rail in a clean, dry environment. Ensure proper grounding and separate power/signal cable routing to avoid interference. Verify voltage compatibility and use ABB’s configuration software to program parameters and test connectivity with peripheral devices.

Installation Preparation:

Mount the UDD406A securely on a DIN rail in a clean, dry environment. Ensure proper grounding and separate power/signal cable routing to avoid interference. Verify voltage compatibility and use ABB’s configuration software to program parameters and test connectivity with peripheral devices.

Maintenance Recommendations:

Regularly inspect for loose connections or physical damage. Update firmware quarterly to access new features and security patches. Clean dust from vents using compressed air. For redundant systems, perform failover tests biannually. Monitor I/O performance and replace worn components promptly to maintain system reliability.

Regularly inspect for loose connections or physical damage. Update firmware quarterly to access new features and security patches. Clean dust from vents using compressed air. For redundant systems, perform failover tests biannually. Monitor I/O performance and replace worn components promptly to maintain system reliability.

UDD406A

Product Warranty

ABB guarantees the UDD406A against defects in materials and workmanship for 12 months from purchase. Coverage includes repair or replacement of faulty components. ABB’s global service network provides 24/7 technical support, remote diagnostics, and on-site assistance. Users gain access to detailed documentation, training resources, and compatibility with ABB’s extensive automation ecosystem, ensuring long-term operational efficiency.

Our company is a professional company engaged in the sales of spare parts for large imported systems (distributed control systems, programmable controllers, redundant fault-tolerant control systems, and robotic systems) for many years.ABB guarantees the UDD406A against defects in materials and workmanship for 12 months from purchase. Coverage includes repair or replacement of faulty components. ABB’s global service network provides 24/7 technical support, remote diagnostics, and on-site assistance. Users gain access to detailed documentation, training resources, and compatibility with ABB’s extensive automation ecosystem, ensuring long-term operational efficiency.

ABB REF542PLUS switch

ABB RF615 AI card

ABB RVC6-5A program module

ABB SA801F module connector

ABB SAFT103 control cabinet node unit

ABB SAFT110 governor

ABB SB512 input module

ABB SC513 AI/AO/DI/DO module

ABB SC610 servo valve

ABB SE96920414 YPK112A Digital output

ABB SK-11 program module

ABB SK829007-B Ethernet

ABB SK829007-B Integrated protection device

ABB SNAT617CHC connection modules

ABB SPAD346C drive

ABB SPA-ZC22 servo

ABB SPCJ4D34-AA eddy current sensor

ABB SR511 monitoring

ABB TA25 DU 32 system

ABB TA524 DCS

ABB TB521-ETH rack

ABB TC625 remote module

ABB TC630 main processor

ABB TK516 pulse input

Our main brands include ABB, GE/Fanuc, Bently Nevada, Foxboro, Triconex, Emerson/Ovation, Motorola,Honeywell,Bosch RexrothXycom,Kuka,Moog,Allen-Bradley/Icx triplex/Prosoft, Pacific Scientific,Woodward, NI, Schneider, Yaskawa, Yokogawa, and other imported automation system spare parts sales and system integration high-tech enterprises. We have a wide range of inventory channels and good prices.

Please feel free to contact us at+86 18859254943

中文版

中文版

Phone:

Phone:  Email:

Email:  WhatsApp:

WhatsApp: