Description

Product Overview

The TRICONEX DI3361 is a high-reliability digital input module designed for safety-critical industrial automation systems, specifically as part of TRICONEX’s renowned Tricon series—a platform celebrated for its triple modular redundancy (TMR) architecture. Engineered to withstand harsh industrial environments while delivering precise and secure signal acquisition, the TRICONEX DI3361 serves as a vital component in systems requiring fault tolerance and deterministic performance, such as safety instrumented systems (SIS), emergency shutdown (ESD) systems, and critical process control applications.

As a digital input module, the TRICONEX DI3361 is designed to interface with a wide range of field devices, including switches, sensors, and contactors, converting their discrete signals into digital data that can be processed by the control system. Its core functionality lies in its ability to accurately capture binary state information (on/off, open/closed) while ensuring signal integrity through advanced diagnostic features and hardware redundancy. Whatsapp:+86 18859254943.The module is part of TRICONEX’s Tricon family, which is built on a foundation of triple redundancy, meaning each critical component is triplicated to provide self-diagnostic capabilities and continuous operation even in the event of a single-point failure. This design ensures that the TRICONEX DI3361 meets the highest safety standards, making it an ideal choice for industries where system downtime or failure could lead to severe consequences, such as oil and gas, chemical processing, power generation, and nuclear facilities.

In the broader context of industrial automation, the TRICONEX DI3361 acts as a bridge between field-level devices and the control system, enabling real-time monitoring and safe decision-making. Its robust construction, combined with advanced signal conditioning and error-checking mechanisms, ensures that it maintains operational integrity in environments characterized by high levels of electrical noise, temperature fluctuations, and mechanical vibration. By integrating the TRICONEX DI3361 into a control system, users can achieve enhanced system availability, reduced maintenance costs, and compliance with international safety standards such as IEC 61508 and IEC 61511.Whatsapp:+86 18859254943.

Technical Specifications

| Parameter Name | Parameter Value |

|---|---|

| Product Model | DI3361 |

| Manufacturer | TRICONEX |

| Product Type | Digital Input Module (Triple Modular Redundant) |

| Input Voltage Range | 24 VDC (±10%) |

| Number of Channels | 16 channels (isolated, 8 channels per submodule) |

| Input Type | Dry contacts or NPN/PNP open-collector signals |

| Signal Filtering | Adjustable software filter (0.1 ms to 100 ms) |

| Communication Protocol | Tricon proprietary backplane communication (10 Mbps, dual-redundant) |

| Operating Temperature | -40°C to +70°C (-40°F to +158°F) |

| Storage Temperature | -40°C to +85°C (-40°F to +185°F) |

| Vibration Resistance | 2 g peak, 5 Hz to 200 Hz (per IEC 60068-2-6) |

| Shock Resistance | 15 g peak, 11 ms (per IEC 60068-2-27) |

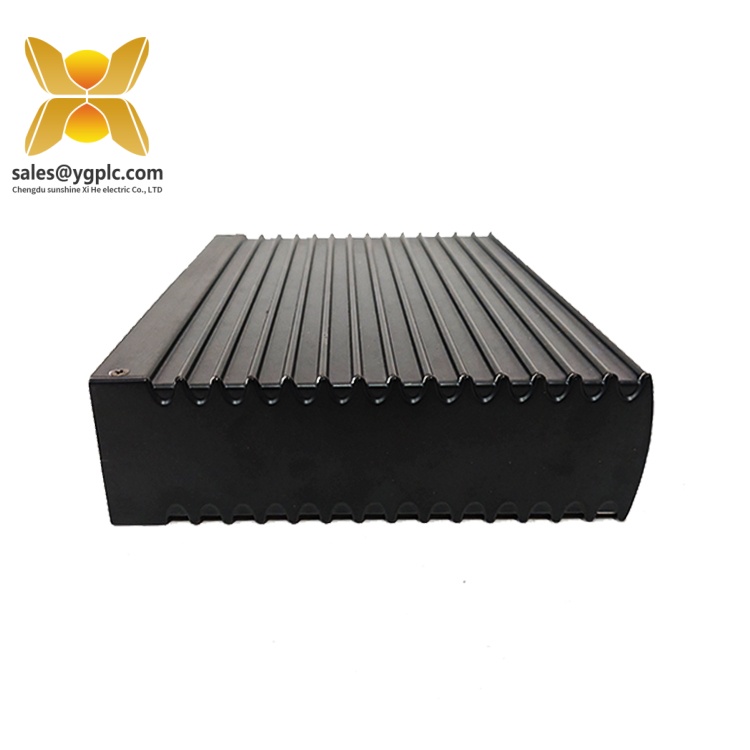

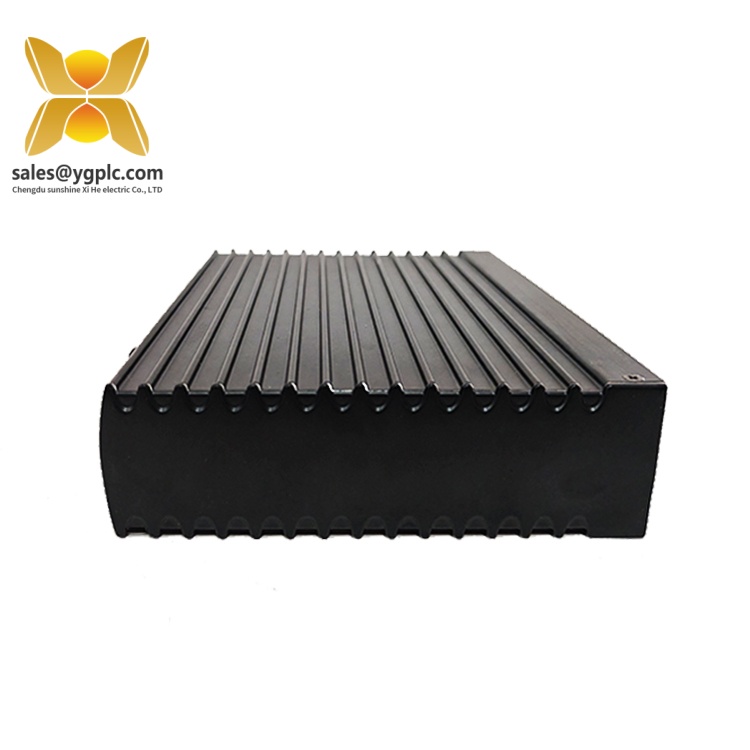

| Physical Dimensions | 175 mm (height) x 100 mm (width) x 220 mm (depth) (6.89 in x 3.94 in x 8.66 in) |

| Installation Method | Rack-mounted (compatible with Tricon 3000/4000 series chassis) |

| Safety Integrity Level (SIL) | SIL 3 capable (when used in a properly configured TMR system, per IEC 61508) |

Main Features and Advantages

The TRICONEX DI3361 stands out in the industrial automation landscape due to its unique combination of advanced redundancy, rugged design, and intelligent diagnostics, making it a benchmark for safety-critical digital input solutions.

Triple Modular Redundancy (TMR) Architecture

At the core of the TRICONEX DI3361 is its TMR design, which triples all critical components—including microprocessors, input circuits, and communication paths. This architecture ensures that the module can tolerate single-point failures without compromising functionality.Whatsapp:+86 18859254943. Each channel’s input signal is independently processed by three identical submodules, with a majority-vote mechanism ensuring that only accurate and consistent data is passed to the control system. This not only enhances system reliability but also eliminates the need for external redundancy modules, simplifying system design and reducing installation costs.

Comprehensive Diagnostic Capabilities

The module incorporates built-in self-diagnostics that continuously monitor its internal health, including signal integrity, power supply stability, and component wear. Diagnostic features such as channel-by-channel fault detection, thermal monitoring, and communication link diagnostics provide real-time feedback to the control system, enabling proactive maintenance and minimizing unplanned downtime. These diagnostics are compliant with industry standards for safety instrumented systems, allowing users to achieve and maintain the required safety integrity levels with confidence.

Flexible and Robust Signal Handling

The TRICONEX DI3361 supports a wide range of input types, from dry contact signals to active voltage signals, making it compatible with virtually any field device. Its adjustable signal filtering allows users to configure noise immunity based on specific application requirements, ensuring reliable signal acquisition even in electrically noisy environments. Additionally, the module’s isolated channels prevent cross-talk and ground loops, further enhancing signal quality and system stability.E-mail :sales@ygplc.com.

Rugged Industrial Design

Built to withstand the harshest industrial environments, the TRICONEX DI3361 features a robust enclosure and thermal management system that supports operation across a wide temperature range (-40°C to +70°C). It is also resistant to vibration, shock, and electromagnetic interference (EMI), meeting or exceeding international standards for industrial durability. This makes it suitable for use in offshore platforms, refineries, and other harsh environments where equipment failure is not an option.

Seamless Integration with Tricon Systems

As part of the Tricon family, the TRICONEX DI3361 integrates seamlessly with other Tricon modules and controllers, enabling users to build scalable and highly available systems. .E-mail :sales@ygplc.com.Its standardized backplane communication protocol ensures fast data transfer and synchronization across the entire control architecture, while its hot-swappable design allows for module replacement without powering down the system—an essential feature for maintaining uptime in critical applications.

Application Areas

The TRICONEX DI3361 is ideally suited for applications where safety, reliability, and precise signal monitoring are paramount. Its robust design and TMR architecture make it a preferred choice in industries such as:

Oil and Gas Production

In upstream and downstream oil and gas facilities, the TRICONEX DI3361 is used to monitor critical safety signals from valves, pumps, and emergency shutdown devices. It ensures that any abnormal conditions, such as high pressure or temperature spikes, are accurately detected and responded to in real time, protecting personnel and equipment from potential hazards.

Chemical and Petrochemical Processing

Within chemical plants, where process variability and safety risks are high, the module captures discrete signals from sensors and switches involved in reaction control, material handling, and fire and gas detection systems. Its ability to handle harsh environments and maintain signal integrity is crucial for preventing accidents and ensuring compliance with strict safety regulations.

Power Generation

In thermal, nuclear, and renewable power plants, the TRICONEX DI3361 plays a key role in monitoring the status of circuit breakers, generator controls, and safety interlocks. Its redundancy features are essential for maintaining grid stability and preventing cascading failures in power distribution systems.

Pharmaceutical and Biotechnology

In highly regulated industries like pharmaceuticals, where process consistency and safety are non-negotiable, the module is used to monitor sterilization equipment, valve positions, and safety interlocks in cleanroom environments. Its precision and reliability help ensure product quality and regulatory compliance.

Industrial Safety Systems

As a critical component of safety instrumented systems (SIS), the TRICONEX DI3361 enables the safe monitoring of process variables and the activation of protective measures when abnormal conditions are detected. It supports the highest SIL 3 safety levels, making it suitable for applications where a single point of failure could have catastrophic consequences..E-mail :sales@ygplc.com.

Related Products

The TRICONEX DI3361 is part of a comprehensive ecosystem of Tricon modules designed to work together in creating robust control and safety systems. Below are key related products and their relationships:

- TRICONEX DI3501: A high-density digital input module with 32 channels, ideal for applications requiring a larger number of input signals while maintaining TMR redundancy.

- TRICONEX DO3203: A digital output module complementary to the DI3361, designed to send discrete control signals to field devices, featuring the same TMR architecture for safe output activation.

- TRICONEX AI3100: An analog input module that works alongside the DI3361 to capture continuous process variables, such as temperature and pressure, for a complete process monitoring solution.

- TRICONEX Tricon Controller 4000: The central processing unit of the Tricon system, which integrates data from modules like the DI3361 to execute control logic and safety algorithms.

- TRICONEX FTA3300: A field termination assembly designed to interface the DI3361 with field wiring, providing a secure and organized connection point for input signals.

- TRICONEX DI3401: A digital input module optimized for high-speed signal acquisition, suitable for applications requiring rapid state change detection, such as turbine control systems.

- TRICONEX Power Supply Modules (e.g., PS3040): Redundant power supply units that ensure continuous operation of the DI3361 and other Tricon modules, even during transient power disturbances.

- TRICONEX Communication Modules (e.g., CM3008): Modules that enable the DI3361 to communicate with external systems via protocols like Modbus, Ethernet/IP, or Profibus, enhancing system interoperability.

- TRICONEX IO Expansion Chassis: Additional racks that allow users to expand their Tricon system by adding more modules, including the DI3361, to meet growing input/output requirements.

Installation and Maintenance

Installation Preparation

Before installing the TRICONEX DI3361, ensure the Tricon chassis is powered down and properly grounded to prevent electrical damage. Verify that the chassis model is compatible with the module (e.g., Tricon 3000 or 4000 series) and that the required firmware versions are installed on the controller. Prepare the field wiring by terminating discrete signals to the appropriate terminals on the associated field termination assembly (FTA), ensuring correct polarity and voltage levels for the input type (dry contact or active signal). Label all connections for easy identification and future maintenance. When inserting the module into the chassis, align it with the guide rails and apply gentle pressure until it clicks into place, ensuring a secure mechanical and electrical connection.

Maintenance Recommendations

Regular maintenance of the TRICONEX DI3361 is key to ensuring long-term reliability. Perform periodic visual inspections to check for loose connections, physical damage, or signs of overheating. Use the control system’s diagnostic interface to review the module’s health status, including channel errors, temperature readings, and communication link quality. If a fault is detected, refer to the module’s diagnostic codes to identify the issue—most faults can be resolved by replacing the affected submodule while the system remains online, thanks to the hot-swappable design. Clean the module’s exterior periodically with a dry, static-free cloth to prevent dust accumulation, which can affect thermal performance. Additionally, ensure that the operating environment remains within the specified temperature and humidity ranges to avoid premature component wear. Schedule annual system reviews to validate that the module’s configuration and diagnostics are still aligned with application requirements, especially after any process changes or upgrades..E-mail :sales@ygplc.com.

Product Assurance

We are committed to delivering the highest quality industrial control solutions, and the TRICONEX DI3361 is backed by our comprehensive product assurance program. As a leading industrial control distributor with 17 years of experience, we stand behind every product we sell, offering a standard warranty that covers manufacturing defects and ensures peace of mind for our customers. Our dedicated technical support team is available to assist with installation, configuration, and troubleshooting, providing timely responses to ensure minimal downtime.

Understanding the critical nature of industrial automation systems, we maintain a large inventory of both current and hard-to-find components, including the TRICONEX DI3361, to meet urgent customer needs. Our global supply chain network allows us to deliver products quickly, even for obsolete or legacy systems, ensuring that your operations can continue without interruption. Whether you require a single module or a complete system integration, we are dedicated to providing reliable, efficient, and customer-centric service at every stage—from initial inquiry to post-sales support. Trust in our expertise and commitment to quality as you build and maintain safe, reliable, and high-performing industrial control systems with the TRICONEX DI3361.

TRICONEX 3481 Gas turbine card

TRICONEX AI3351 Communication input interface component

TRICONEX MP3101 Communication output interface component

TRICONEX RO3451 Interface component

中文版

中文版

Phone:

Phone:  Email:

Email:  WhatsApp:

WhatsApp: